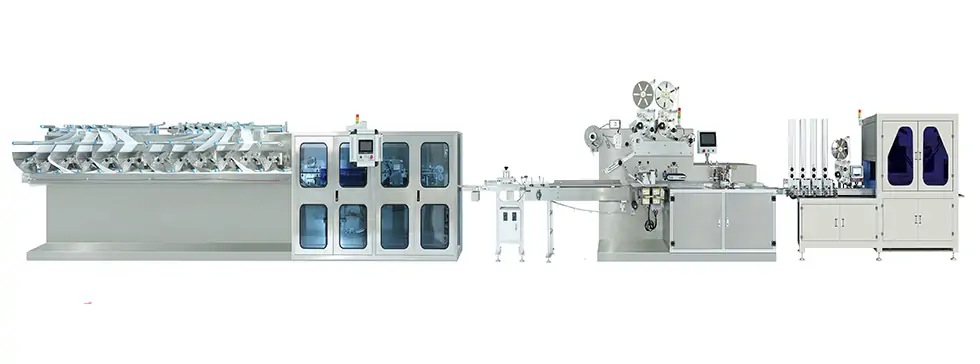

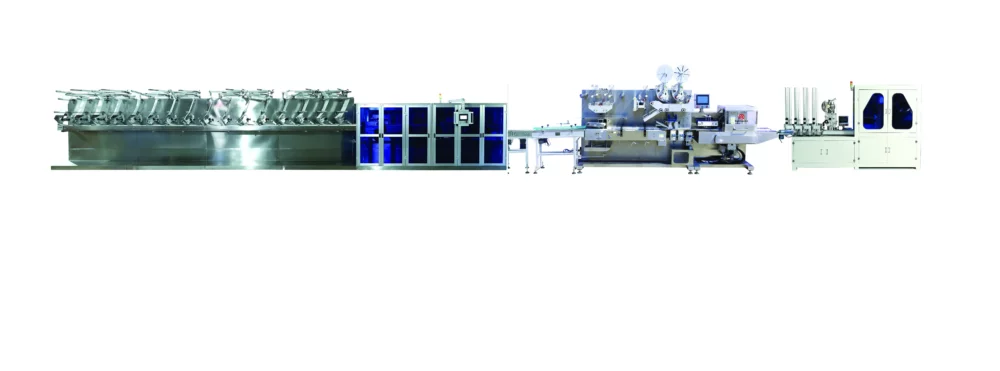

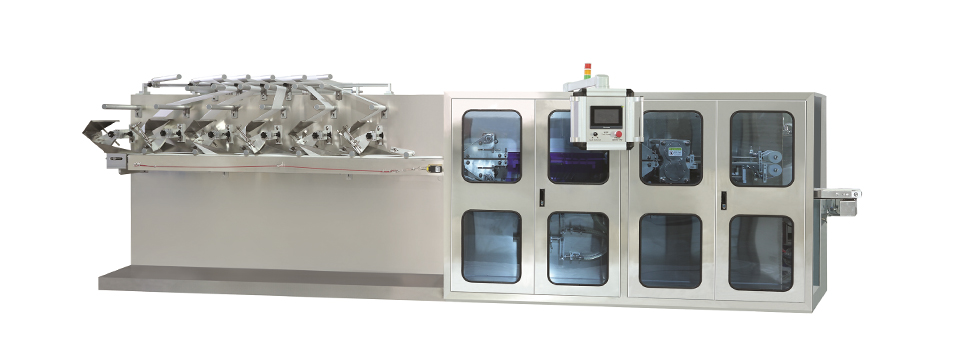

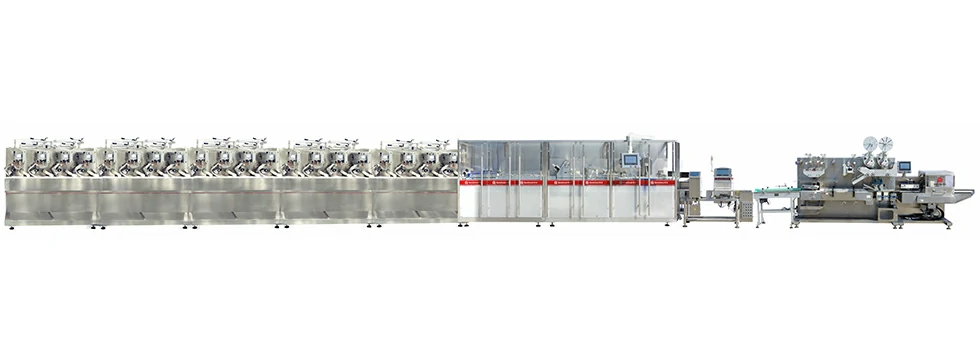

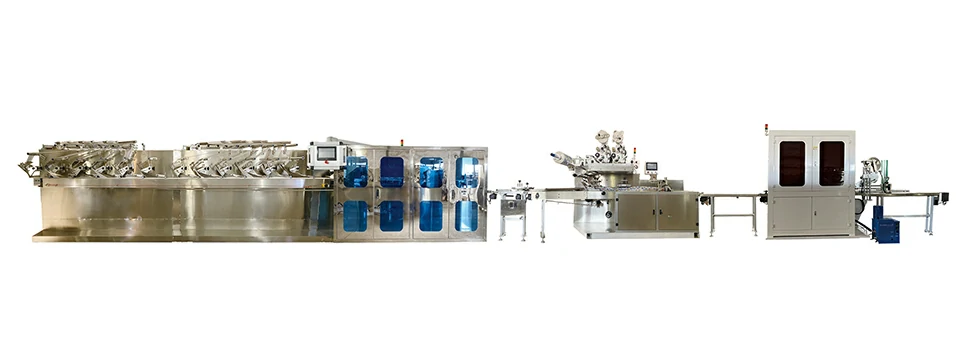

WET WIPES MACHINES

QIANZHAO Produces Kinds Of Wet Wipes Machines

As leading wet wipes machines manufacturer and supplier in China, QIANZHAO provides quality machines equipment for making wet wipes, napkins, wet tissues products.

Working Principle Of Wet Wipes Machines:

Wet wipes machines for baby and adult follow a similar production process as other wet wipes machines. They unwind non-woven fabric rolls, impregnate them with a specialized liquid solution containing mild cleansers and moisturizers suitable for babies’ delicate skin, fold and cut the fabric into individual wipes, and package them in various formats, such as resealable packs or individual sachets.

However, they may use different formulations of liquid solutions tailored to adult needs, such as antibacterial or refreshing properties.

Working Principles Of Sanitary Pad Machine:

Machines for sanitary pad involve components like unwinding units, material layering systems, shaping and cutting mechanisms, and packaging units.

Sanitary pad machines are specialized systems for producing feminine hygiene products, such as sanitary pads and panty liners. They unwind absorbent materials, add adhesive layers, shape and form the pads, and package them hygienically.

How Do Underpad Machines Work?

Underpad machines consist of unwinding units, material layering systems, shaping and cutting mechanisms, and packaging units.

Underpad machines produce disposable underpads used for incontinence management, bed protection, and other medical applications. They unwind non-woven fabric, add absorbent layers, shape and cut the underpads, and package them for distribution.

QIZHAO produces and supplies Types Of Wet Wipes Making Euqipment

- We provides wet wipes making machine with 6, 12, 16, 20 lanes

- Alcohol wet tissue production for 30 – 120pcs

- Canister bottle pack wet wipes machine

- Full-automatic high speed wet wipes machines

- Portable pack wet wipes machine

- Roll wet tissue making machine

- Packing equipment for wet wipes

- Single sachet restaurant wet wipe machines

- Single sachet lenses wet wipe machine

- Wet wipe canister filling machine