products

Product description

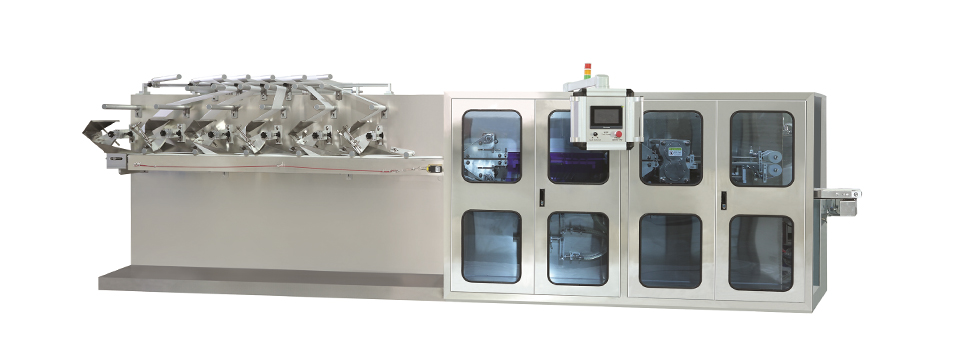

The 6 lanes wet tissue folding machine is used to produce disposable restaurant wet towel, which is popular in restaurant trade.

Production flow:Raw material loading → vertical-folding → tissue wetting → tissue cutting → tissue counting and stacking → tissue delivery

Features

1.Professional manufacturer

2.Top quality

3.Full servo automatic control

4.Easy operation

5.Quality assurance

6.Hygiene products converting solution

7.Customized service

8.Main supported parts from world famous brands.

Application

The machine is powerful enough to produce a wide range of wipes, including adult wipes, car cleaning wipes, baby wipes, washable laundry wipes, wet wipes, cleaning and household wipes, industrial wipes, and jumbo wipes. The automatic wipe dispenser makes it easy to change between different products. This makes it very flexible and fully responsive to present and future market needs.

Parameters

Samples

Structure

Stainless steel is applied to the cover of machine and main spare parts. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product meets hygienic standard. The folding device is specially designed to make various folding ways feasible. It’s smart and speedy.

Detail

Request A Quote