products

Product description

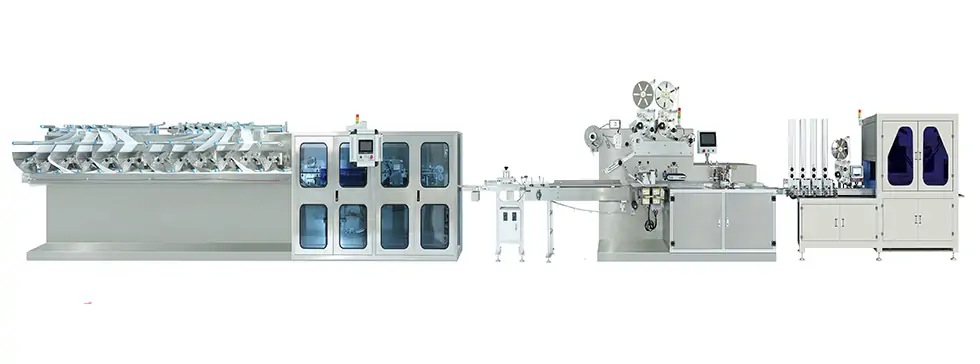

This machine produces single-piece wipes suitable for takeout and catering industries. Each wipe is individually packaged and is typically used to clean hands.

The machine can automatically complete: folding wet tissue, cutting, spraying medicine liquid, slitting, bag forming, sealing, counting, printing batch number, finished product output etc. And it can avoid the secondary pollution during packing of wet tissue. The whole machine has compact structure, suns in security. It is your first choose of wet tissue packing equipment.

Raw material loading→ wetting →vertical-folding→ tissue cutting →half folding →tissue packing → finished product

Features

1.Professional manufacturer

2.Top quality

3.Full servo automatic control

4.Easy operation

5.Quality assurance

6.Hygiene products converting solution

7.Customized service

8.Main supported parts from world famous brands.

Application

Single-piece wet wipe can be used in various life scenarios. It is very convenient to carry when going out. Equally suitable for use around the house or for more intensive commercial use in restaurants and bars

Parameters

Samples

Structure

Stainless steel is applied to the cover of machine and main spare parts. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product meets hygienic standard. The folding device is specially designed to make various folding ways feasible. It’s smart and speedy.

Request A Quote