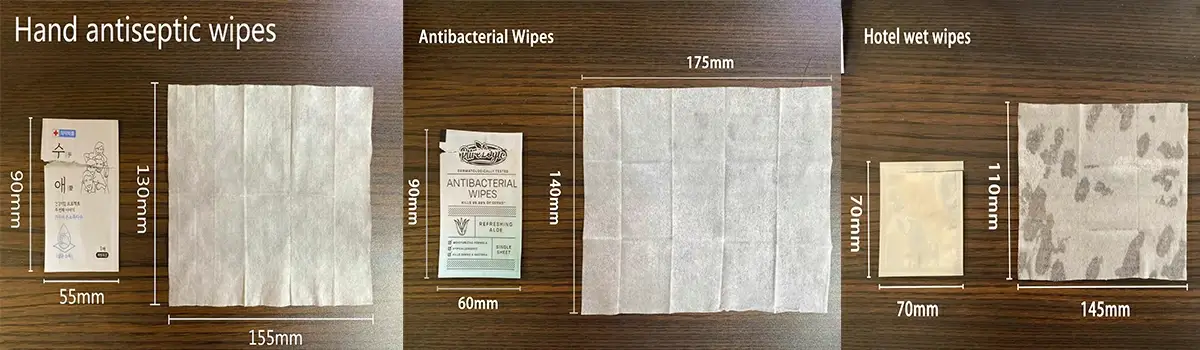

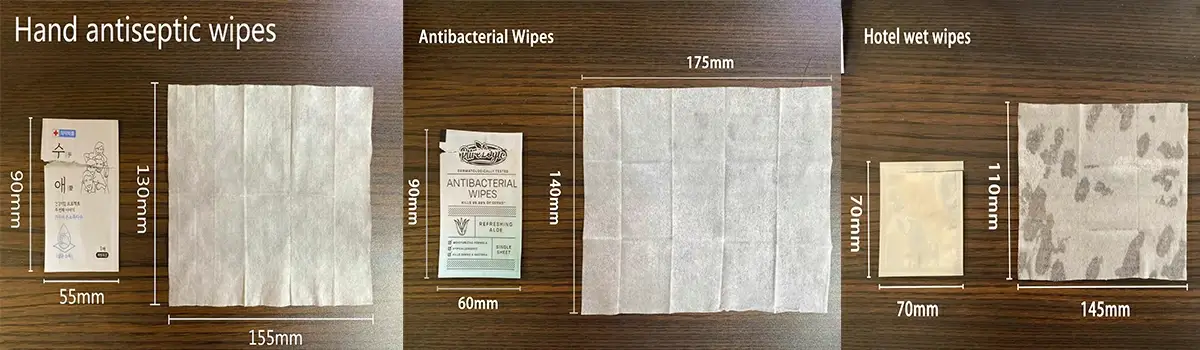

Product Type:

This machine is suitable for the production of all kinds of four-side sealing wipes, make-up removal wipes, personal care wipes, alcohol pads, etc. One machine can produce a variety of different package sizes products(wet wipes).

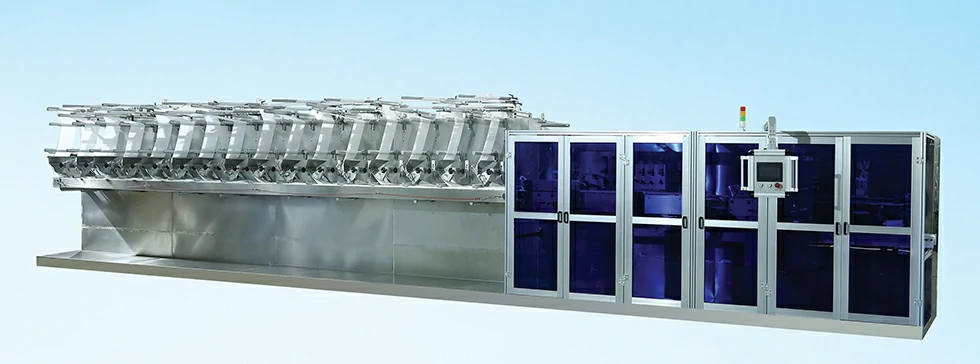

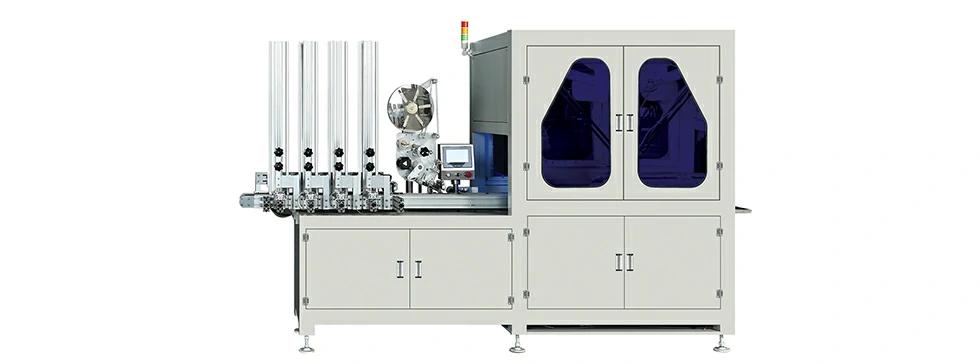

Work Flow:

Loading one packing film roll→1st Sealed(Left+right+bottom sides)→Loading two non woven rolls→fold→cutoff→Insert tissue & fill liquid→2nd sealed(Left+right+up+bottom sides)→embossing Lot No.→tear/notch making→cut off & output by robot arm.

Main Technical Parameter:

| Packaging Form |

Four-size Sealing |

| Packing Material |

CPP,PE,PET,,OPP,BOPP/AL Laminated film |

| Inner Material |

30-80g/㎡ air laid paper, nonwoven, spun lace nonwoven fabric etc. |

| Material Inner Roller Dia. |

Φ70-75MM |

| Packing Size Length X Width |

(40—125) X (40—110)MM

the bag size is adjustable ,change size no need change mold |

| Nonwoven roll out -diam. |

1000mm |

| Package roll out-diam. |

350mm |

| Folding Way |

Max 10 times folding vertical, and 4 times folding horizontal |

| Liquid Added Range |

0-10ml |

| Packing Speed |

60-120 bags/Min |

| Total Power |

2.8KW |

| Power Supply |

220/380V 50/60HZ |

| Machine finishing |

Stainless steel |

| Machine Noise |

≤64.9DB(A) |

| Output |

Packing arm will collect the products and put it onto conveyor,the desired number of the stacks,it can be adjusted and set on the control panel |

| Air Supply |

0.6-1.0 MPa |

| Air Consumption |

300-500ml/min |

| Machine Dimensions |

3000×2500×1800(L*W*H) |

| Machine Weight |

About 1200kgs |

Packing and Delivery: