products

Product description

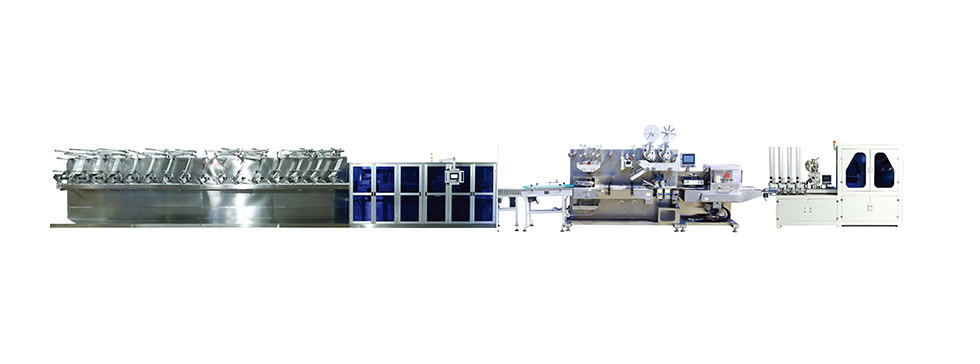

This machine is used to produce wet wipes in cans or buckets. These types of wipes are commonly used for personal care and household cleaning purposes.

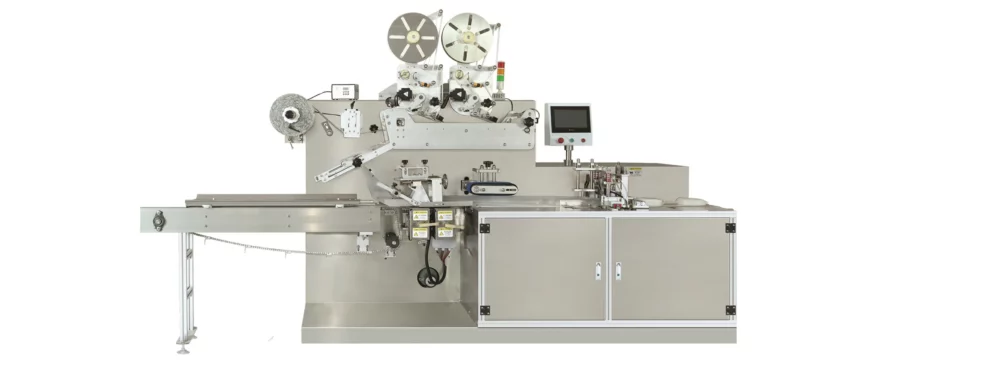

The machine has loading device (air pressure control), slitting device, conveyor device, perforating device, punching device. It adopts air pressure knife control (10 knives), smooth cutting surface. Conduit adopts stainless steel with small resistance. It is controlled by PLC, high speed and stable. The punching device adopts circular knife, the length is adjustable.

This canister wet wipes machine produces wet wipes with different diameters and different ca heights. They are more suitable for use at home or in fixed places and have a larger capacity.

Production flow:raw material loading — folding — automatic wetting — automatic cutting — stacking— tissue output

Machine technical parameters

Application

This machine is for making canister wet wipes, pet bottle wet wipes,dry towel.

Samples

Structure

Stainless steel is applied to the cover of machine and main spare parts. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product meets hygienic standard.

Packing and Delivery

Request A Quote