products

Product description

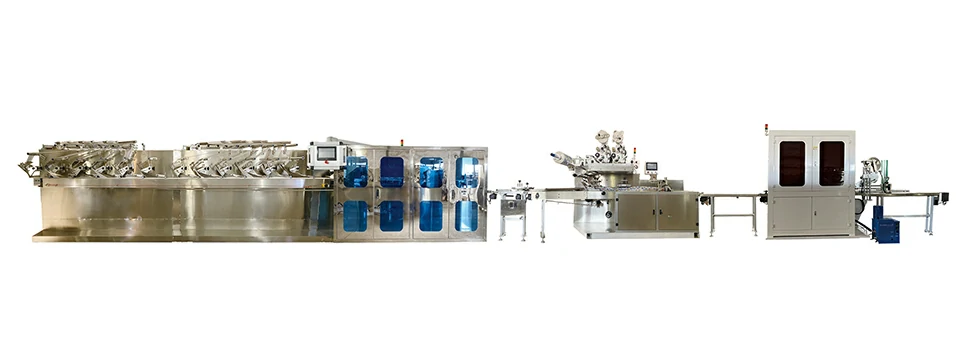

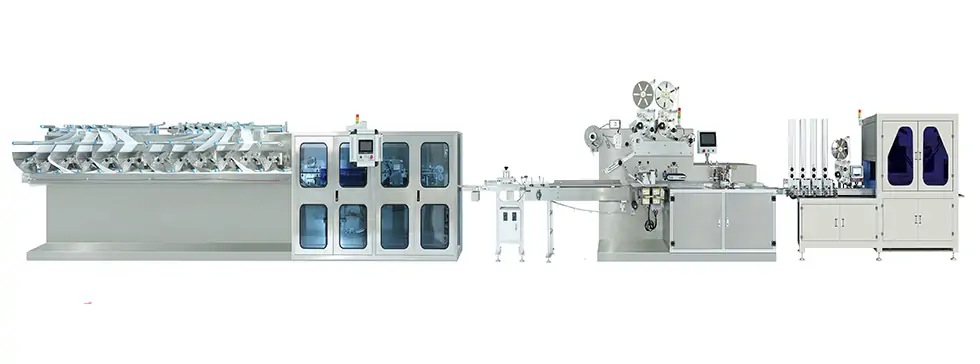

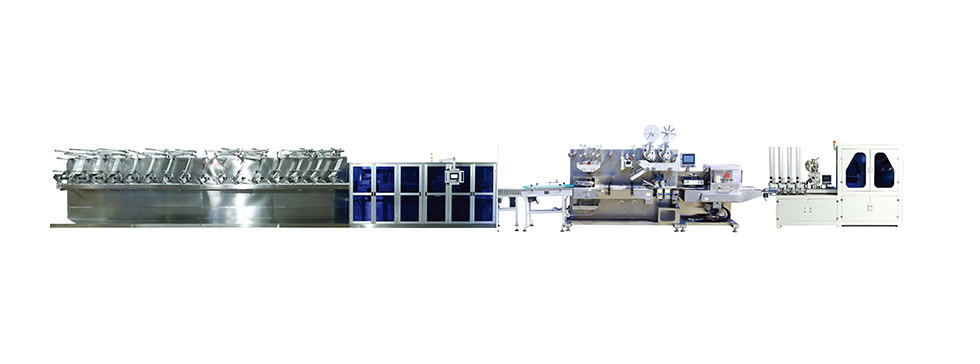

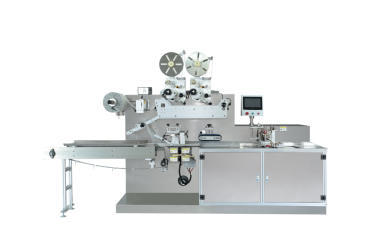

This is a wet wipes packaging machine suitable for packaging 30-120 pieces per pack

The wet wipes packaging machine is designed to pack 30-120pcs in one bag. Reciprocating end-sealing packaging and precise trimming wheel design ensure beautiful and accurate packaging, which saves space and manpower. The packaging range can be configured as needed to stabilize the speed 45-50 bags/m. The entire machine configuration considers customer needs to save costs and improve performance. It is a cost-effective wet wipes packaging machine.

Product introduction

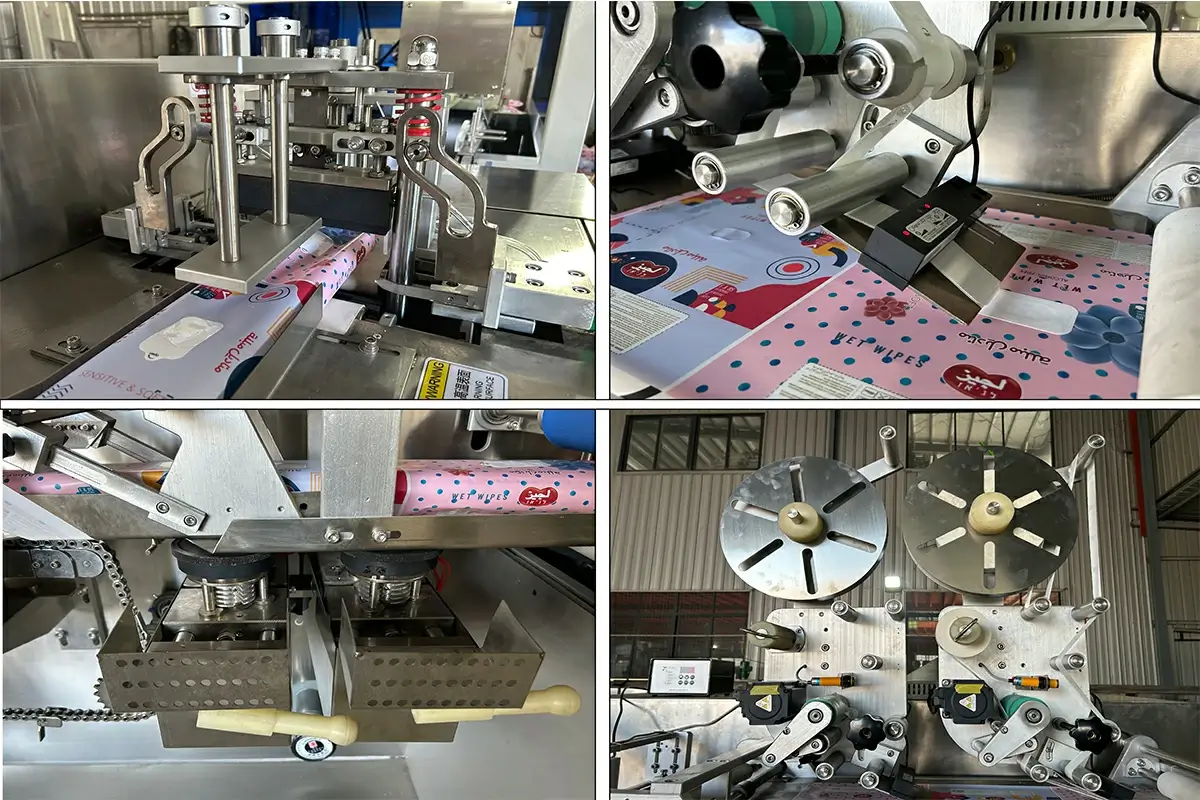

tissue conveyor → film date Printing → packing film punching → auto labeling→bag forming → Auto bags sealing → products finished

Machine technical parameters

Application

This machine can pack 30-120pcs per bag. Size and appearance of outer packaging can be customized by your needs so as to make it look better to attract more customers. The machine adopts PLC control and touch screen operation, making the setting of different parameters very fast, simple and intuitive.

Samples

Structure

The machine is equipped with a gusset mechanism. It is an innovative multi-purpose machine that can greatly reduce the equipment purchase cost of enterprises. The machine has novel structure, advanced technology and high production efficiency, which solves the defects of cross-contamination caused by manual packaging. The external structure of the machine and parts in contact with the machine body and products are made of stainless steel and non-toxic materials.

Packing and Delivery

Request A Quote